Innovative in Sack & Silo

Research and development is very important to us, because only those who constantly innovate can enjoy sustainable market success. Innovation begins at Bergmann Kalk long before the actual product, from efficient production technology through state-of-the-art machine technology to pioneering product development. Bergmann takes on this challenge every day. Extensive, multi-million investments in research and development allow us to take completely new and – more importantly – productive approaches. As a medium-sized company, we do not think in terms of financial quarters, but in whole entrepreneurial generations.

Research and Development Center

m-tec: A silo for every purpose

Qualical: The Future of Lime Burning

Development partner of the dry mortar industry

Since 1978, Bergmann Kalk has been an active development partner in the dry mortar industry. As a founding company of the Franken Maxit Mauermörtel GmbH, Bergmann Kalk is constantly involved in the development of new product solutions. Under the world-famous building material brand maxit, a large number of innovative products for solving completely individual construction challenges have already been developed and successfully put on the market. Bergmann Kalk is, as a consequence, in possession of a considerable number of international patents and industrial property rights.

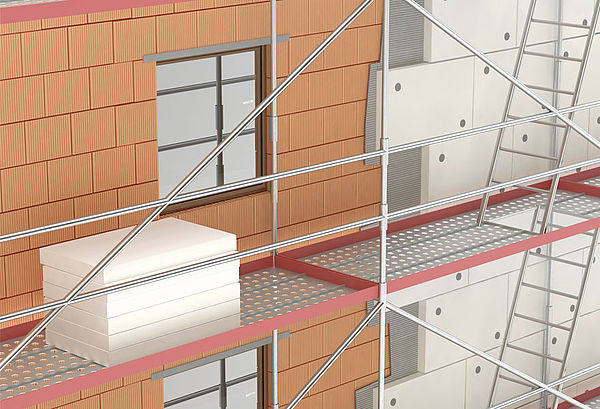

The maxit mortar pad – The smart wall

We were able to present a true revolution in masonry construction at the leading international trade fair for construction, the BAU 2015 in Munich.

Open the pack – just add water: With the maxit mortar pad, the processing of masonry reaches unprecedented heights. The maxit mortar pads combine the strengths of traditional applications with meaningful innovation. Intuitive, quick and safe construction – the new masonry 3.0.

ecosphere at maxit and Bergmann Kalk

This year, Bergmann Kalk and maxit celebrate the birth of a completely new generation of construction material. A marriage of glass and mortar: Supported by the Federal Ministry of Education and Research (BMBF, Berlin), the paint, plaster and mortar specialist maxit, working with Bergmann Kalk (Azendorf), has developed a completely new building material technology –the ecosphere insulation system. The technology was initially applied to interior wall insulation, and subsequently to mortar-based facade insulation, with hollow glass microspheres used as a lightweight aggregate. This ensures the best results in terms of thermal insulation, minimum weight and long-term stability. Its special feature: The mineral material can be sprayed directly from the building material silo, resulting not only in a completely seamless application, but also making it easy to work with. ecosphere will be introduced to industry experts for the first time at BAU 2019 in Munich.

maxit winter mortar

In 2017, maxit multi 292 EIS winter adhesive and reinforcing mortar was presented as the building material industry’s first adhesive mortar. It is a real problem solver for the construction trade. Extensive research and development work laid the groundwork for this mortar’s ability to maintain its hardening and setting properties, even at temperatures as low as -8 ° C. Due to its resilience to temperature fluctuations, it is particularly suitable for the transitional periods of the year: In spring and autumn, where the night and day temperature can vary greatly, it ensures the highest level of processing safety.