Our company – Bergmann Kalk for over 110 years

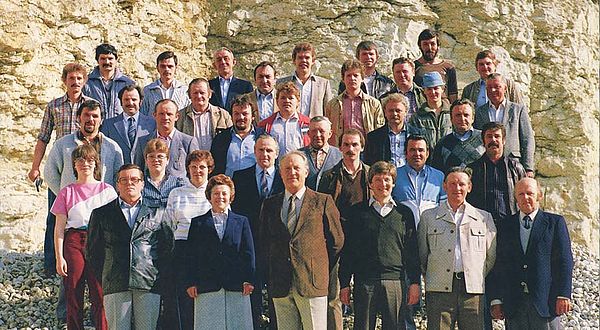

Bergmann Kalk has been successfully mining in Azendorf for more than 110 years and is now owned by the fourth generation of the Groppweis family. Our high-quality natural limestone, which is the raw material for a large number of different lime-based applications, is extracted from the quarries close to the works in open-cast mining. State-of-the-art, computer-controlled plant technology – with the most modern PFR lime kiln in Europe – together with an experienced team of employees ensure the quality of our premium products.

A reliable and fluent production process – from the blasting to the finished product – guarantees the punctual delivery of our products to our customers. The constant control of the individual production steps by our in-house laboratory ensures the consistent quality of the products.

Philosophy

Our mission statement is characterized by sustainability and internationality. Bergmann Kalk is a traditional medium-sized company that takes responsibility for its employees and the region. We think in generations instead of financial quarters. This philosophy is reflected in our resource-conserving approach to natural raw materials, as they are the basis of our natural products.

Mission statement

Quality is the basis of our entrepreneurial success. That is why the needs and wishes of our international customers have top priority for us. We meet this demand with our reliable products, our services, our competent advice, and our smooth and punctual order processing. In this way, we ensure our customers’ orders are secure, and thus corporate earnings and jobs.

Occupational safety and environmental protection are central elements of our corporate policy. This can be seen in our introduction of an integrated management system.

The certified quality management system, in accordance with DIN EN ISO 9001/2000, was introduced as long ago as 2005, and is based on the principles formulated in our corporate policy. In our quality concept, both the quality of the product and the quality of our employees’ teamwork – as well as the relationship with our customers – adhere to the same high standards. The achievement of customers’ satisfaction through consistent delivery of products that meet customer requirements, are of impeccable quality, and are not only reliable but also good value for money, is what we consider key to the long-term success of the company.

Our QM system is aimed at continuously improving the quality of our products and services, and adapting them to the technical and economic requirements of our customers, with the aim of achieving the greatest possible customer satisfaction.

We place particularly high demands on the production of our straight feeding stuffs. A hazard analysis and the monitoring procedure, in accordance to the HACCP concept, ensure that all feed produced in our company complies with the legal requirements, guaranteeing customer satisfaction.

Furthermore, in 2005, we received certification of compliance with QS criteria in the meat production chain (in the stage ‘single feed producer’ in the context of the QS food inspection system). In 2008, this was extended to ‘road transport (animal feed)’ in accordance with the GMP standard.

Research and Development

Together with Franken Maxit, a new research and development center was built on the factory premises in Azendorf. In addition to the continuous further development of dry mortar products, ways of optimizing lime production are also being researched here. The formulation of lime mixtures on behalf of customers is also carried out in the modern production complex.

The new company laboratory for the control of lime products has also been set up on the premises. Close monitoring is a prerequisite for the manufacture of high-quality products: In addition to continuous production control, every customer delivery is also checked before leaving the factory premises.

The company laboratory is equipped with state-of-the-art laboratory equipment. This enables us to offer a wide range of analyses to our customers.

Environment and Sustainability

The companies Johann Bergmann GmbH & Co. and Franken Maxit Mauermörtel GmbH & Co. have committed themselves to continuously reducing energy consumption and to improve both energy efficiency and energy use. In order to achieve this goal, we have introduced an energy management system according to DIN EN ISO 50001/2015. We ensure that all the requirements of this standard are correctly implemented and that the processes within this energy management system are constantly improved. In doing so, we also commit ourselves to ensuring the availability of information and the necessary resources to achieve our strategic and operational goals, and to comply with all applicable legal requirements regarding energy-related performance.

In addition, we regularly check whether

- the necessary financial and structural conditions are in place

- all employees are integrated into the implementation and execution of the management systems

- the improvement of energy-related performance is supported by the purchase of energy-efficient products and servicesthe energy policy within the organization is documented and communicated across all levels, and is regularly reviewed and updated as necessary

Quality

“Our particular strength lies in the high technical standard that we have achieved. The density of our locations in Germany and the Czech Republic and our international orientation also play a decisive role. This enables us to reach every customer in the shortest possible time and guarantee a constant readiness to deliver,” says Sebastian Groppweis, Managing Director of Bergmann Kalk, which co-founded the maxit Group.

The quality and energy management system is based on the principles formulated in our corporate policy. . In our quality concept, both the quality of the product and the quality of our employees’ teamwork – as well as the relationship with our customers – adhere to the same high standards, as one inseparable unit . Achieving customer satisfaction leads to the long-term success of the company. Our QM system is aimed at constantly improving the quality of our products and services and adapting them to the technical and economic requirements of our customers, with the aim of achieving the greatest possible customer satisfaction.

We place particularly high demands on the production of our straight feeding stuffs. A hazard analysis and the monitoring procedure, in accordance to the HACCP concept, ensure that all feed produced in our company complies with the legal requirements. Customer satisfaction is achieved through consistent delivery of products that meet customer requirements, are of impeccable quality, and are not only reliable but also good value for money.

The history of the company since its foundation in 1908

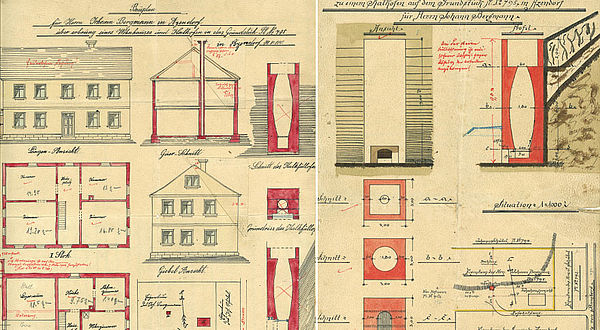

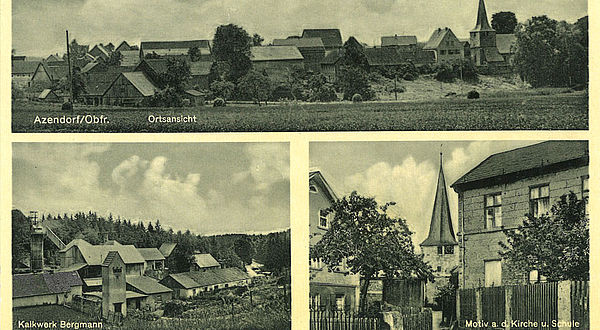

Lime mining has a tradition of more than 110 years in Azendorf. As early as 1908 the company founder Johann Bergmann, grandfather and great-grandfather of the current shareholders Hans-Dieter and Sebastian Groppweis, respectively, built a lime kiln in the Azendorf district of the municipality of Kasendorf, thus laying the foundation for the successful development of the company. The burnt lime was used by construction companies as building lime for bricklaying and plastering, as well as in agriculture in the surrounding area as fertilized lime. The term ‘immediate surroundings’ was used at the time to refer to a maximum distance of 30 km around the Azendorf plant.

1908

Company foundation by Johann Bergmann

Construction of a lime kiln

Start of the production of heavy concrete blocks, window ledges, and cement bricks

1934

Johann Bergmann dies at the age of 55

1946

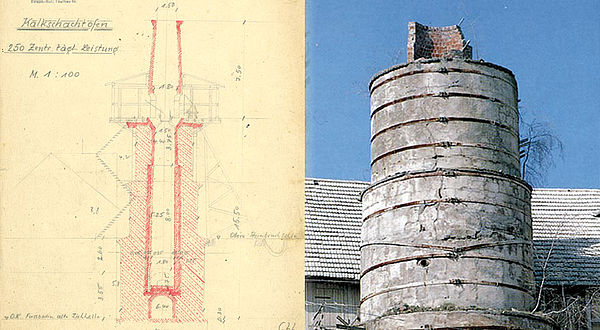

Construction of a brick lime kiln

1949

Construction of a steel jacket furnace with automatic loading

1950

2nd generation: Hans and Albertine Groppweis

1953

Construction of a gravel plant in Azendorf

1964

Construction of a stone grinding plant for the production of limestone powder for road construction and the glass and animal feed industries

1966

Production of limestone sand (0-1 mm) for the glass and dry mortar industry

1973

Construction of a gas-fueled multi-chamber shaft furnace

1978

Hans Dieter Groppweis joins the family business as the 3rd generation

Foundation of Franken Maxit Mauermörtel

Entry into dry mortar production

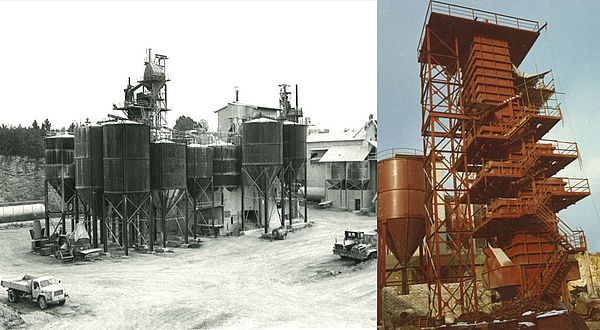

1982-1987

Expansion of limestone sand production to include Plants ll and III

New construction of the primary crushing plant

1989-1990

Border opening of the GDR and foundation of maxit building material plants in Thuringia with the takeover of the Krölpa gypsum plant

1992

Construction of a new concrete ballast plant in slipform construction and construction of a 20 m high noise protection wall

1993

Hans Groppweis dies after a short, serious illness

He played a major role in the growth of the Bergmann lime works and laid the foundation stone for the Franken Maxit Group

1994-1996

Renewal of the infrastructure: the old giving way to the new

Demolition of old residential and office buildings

New construction of a truck scale and a filling station; new truck parking lot

1996

The second furnace generation of a multi-chamber shaft furnace

1998

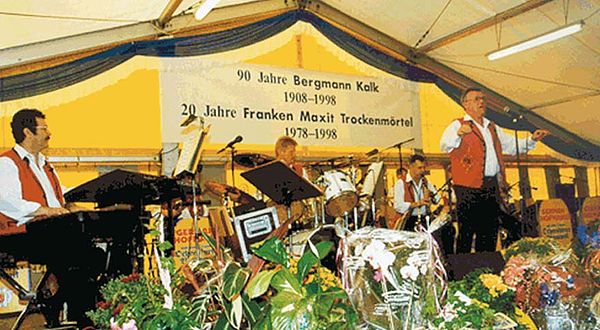

Great celebrations on the occasion of the 90th anniversary of Bergmann Kalk and the 20th anniversary of the company Franken Maxit with guest of honor Minister of State Dr. Wiesheu

2003

25 years Franken Maxit and 95 years Bergmann Kalk are celebrated

Among the guests of honor was Minister of State Dr. Werner Schnappauf

2005

Introduction of a QM system according to DIN EN ISO 9001 and certification according to HACCP for single feed production

2008

Double anniversary – 100 years Bergmann Kalk and 30 years Franken Maxit

2009

Mining permit for a further 30 hectares, south quarry

2011

New mixing plant for soil binders

2013

Reconstruction of the sand plant II

2015

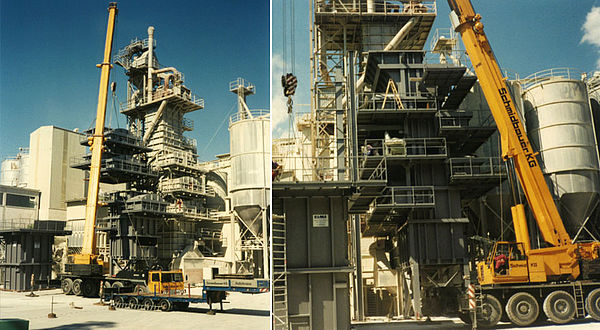

New construction of a PFR lime kiln at the Azendorf site

Application for Quarry Extension North II

2016

Opening of the OFR lime kiln with Minister of State Ilse Aigner

Opening of the mortar pad plant

2017

New research and development center in Azendorf:

The new laboratories in the research and development center go operational

2018-2020

The 4th entrepreneur generation – Sebastian Groppweis becomes Managing Director.

Export activities are intensified with company involvement in New Zealand and Thailand.