Bergmann Kalk Dry Mortar

As the founding company of Franken Maxit Mauermörtel GmbH, Bergmann Kalk has been a force for development in the dry mortar industry for three decades. Since 1978, the company has been actively involved in the development of innovative product solutions. Over the years, innovative solutions for individual construction challenges have been developed and placed on the market under the world-famous maxit brand. The fact that Bergmann Kalk currently owns a large number of international patents and industrial property rights is clear evidence for the philosophy of innovation that has been put into practice at the company.

Our Partnerships:

New Zealand – EZY MIX New Zealand

Founded in 1998, Nu-Age can look back on 20 very successful years in the production and sale of dry mortar products, e.g. for plasters and screeds, at its plant in Matamata, New Zealand. Nu-Age and Bergmann Kalk have been working in a close and friendly collaboration for years.

In 2018, Bergmann Kalk and Nu-Age decided to become partners. The two companies are entering into a technical and economic cooperation to boost the professional development and expansion of the Matamata plant, with the aim of securing market leadership for industrial mortars under the company name EZY-MIX in New Zealand.

Thailand – CHEMEMAN Thailand

The Chememan Group Thailand is the market leader in the South East Asia region for the production of burnt and unburnt lime products. The successful combination of the immense market experience of the company Chememan and the decades of experience in the production of dry mortar products of the Bergmann Group forms the basis of a successful partnership. In 2018, Chememan and Bergmann Kalk agreed to collaborate on the construction of a dry mortar plant on a modular basis with a capacity of between 10,000 and 100,000 tons of dry mortar per year. While the well-known standard products are marketed under the Chememan building materials brand ChemeMix, highly innovative products are marketed under the Bergmann building materials brand Bergmann Eco.

China – Bergmann ecosphere clever coating

Bergmann Kalk has been involved in the Chinese markets for years. Partnerships with successful sales companies guarantee that Bergmann paints based on hollow glass microspheres – made in Germany – enjoy great popularity in the Chinese market. Bergmann ecosphere interior and exterior paint is considered a real problem-solver when it comes to avoiding algae and mold infestation on facades and interior walls.

Germany – Naturbaustoffe Huppenberger – building with straw

Green, resource-saving and non-toxic construction, in short: the development of an eco-friendly insulation material – the team around company founders Gerhard Huppenberger and the head of Bergmann Product Management Johannes Eberlein worked on this idea for years.

The question of the right raw material was quickly answered: straw, with its numerous positive properties, has been used for centuries as an insulating material for houses. The real challenge here was making an ecological binder and developing the process technology for economical industrial production. The fantastic result: straw insulating panels as an environmentally friendly insulation material, 100 per cent sustainably produced and fully recyclable.

The partnership is also fantastic: since 2020, the Huppenberger and Bergmann Kalk companies have been working closely in a joint venture.

Support

Bergmann Kalk can profit from over 110 years of experience in the lime industry. This accumulated knowledge not only flows into the new development and improvement of products: With our know-how, we also offer practical support to our partners on site. For particularly unusual challenges, our trained team is available on site within a short time to find the right solution to any problem.

We are also a reliable partner in international market development. Depending on the production volume, we develop tailor-made production approaches in a modular system.

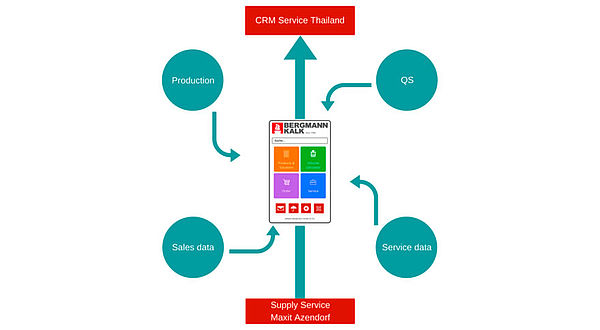

In the near future we will also make our entire know-how available in the app Industry Support 4.0. Here, users will not only find a service module for the provision of production data, but an accompanying sales module also simplifies the sales process for our partners.

Success with Bergmann: Know-how Transfer

More than 110 years of experience in the extraction, processing, and refinement of limestone form the basis for the reliable, high-quality, and permanently economical production of dry mortar and mixtures of binders, aggregates, and additives for the construction industry. Whether masonry mortar, interior and exterior plasters, concretes, flooring systems, or tiling products – Bergmann Kalk guarantees innovative construction solutions.

With our know-how, the latest technologies, and computer-controlled mixing plants for dry plasters, dry mortars, and screeds, we ensure the international production of the best products with consistent quality.

Qualified specialists in our in-house, state-of-the-art laboratories ensure product safety for your market as well, continuously developing new materials, and always taking into account the requirements of international markets in terms of energy savings and environmental compatibility.

On-site support

You too can benefit from Bergmann on-site support! For special challenges in production and packaging, an experienced team of technicians, plant operators, and other specialists is at your disposal. Around the globe, and within a few hours, the Bergmann specialists will take care of your needs.

Of course, the Bergmann team at the parent site in Azendorf in Upper Franconia is also there to help and advise you. An experienced team of employees, encompassing laboratory, technology, and sales and marketing will support you in the development of your international markets.

Modular Mixing Plants for the international market development

Depending on market volume, structural conditions, or simply on the individual requirements of our local partners, Bergmann Kalk offers a tailor-made production approach. With our MMPs – the Modular Mixing Plants – we provide you with a complete dry mortar plant based on containers. Regardless of whether your calculations assume an annual capacity of 10,000 or 100,000 tonnes – we will put together the Bergmann MMPs for your area of application in a modular system. Of course, we will also help you to optimize or expand your existing production capacities.

Industry Support 4.0

With the Bergmann App you are always in good hands, as one of our production partners. In the service module of the app, your production data are checked on the tried-and-tested Bergmann computers at all times and in every single process for compliance with the highest quality standards. If necessary, our specialists will immediately intervene in the production process in order to eliminate malfunctions at an early stage in order to avoid failures. Of course, you can also contact your service technician at any time, e.g. via Skype or e-mail, and discuss things face to face.

The sales module of the Bergmann App offers your dry mortar customers a variety of advantages on site. From round-the-clock access to all product data and the calculation of necessary material quantities to the actual ordering process, your processor or trade customer will always have the right product available in the right quantity and at the right time. In addition, the supervision of your sales staff or application technicians can also be realized via the Bergmann app.

Of course, all your order data flow into the production planning of your Bergmann MMP. They form the basis for a suitable formulation, optimal machine utilization, and timely delivery of the ordered goods.